The standard size of detachable packing container house is 6 meters in length * 3 meters in width * 2.8 meters in height. It is a new product derived from the advantages of detachable container house and packing container house. This product is the first source factory in the industry that integrates R&D, design, manufacturing and sales.

| Availability: | |

|---|---|

| Quantity: | |

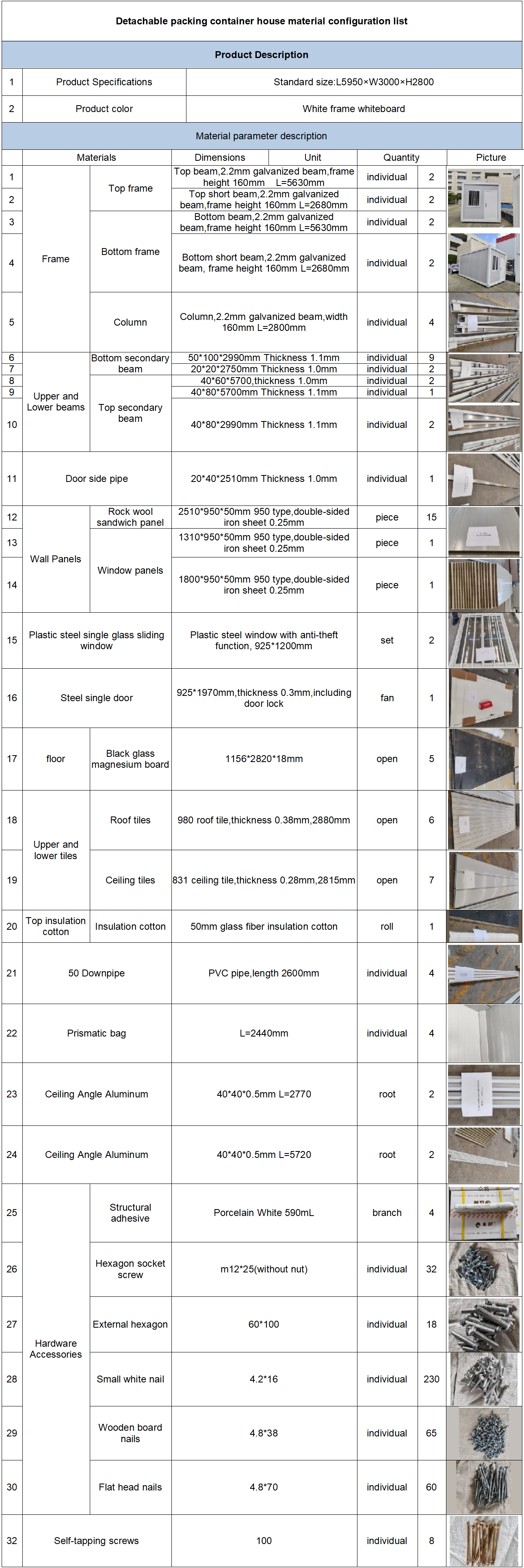

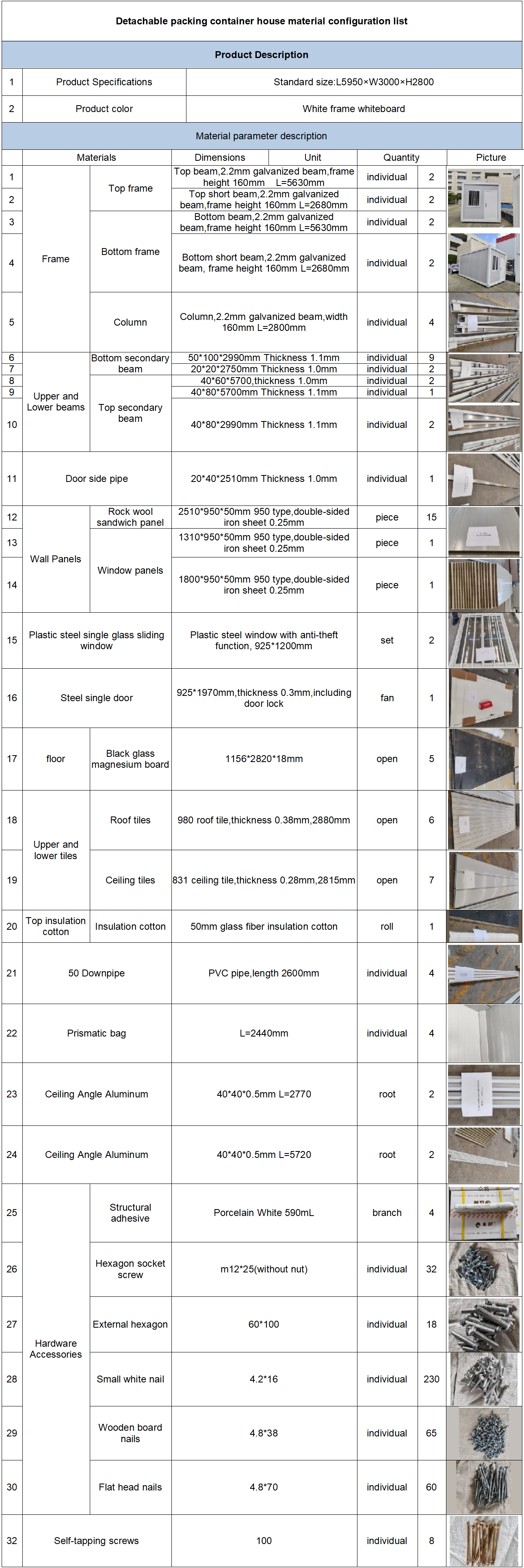

The 2.5mm thickness Detachable Packing Container House is a modular housing solution designed for flexibility and durability. Constructed with a 2.5mm galvanized steel frame, it features a standard external dimension of L5950×W3000×H2800mm, ensuring structural stability and resistance to corrosion. The house integrates high-quality components such as rock wool sandwich panels for walls, plastic steel sliding windows with anti-theft functions, and a steel single door, providing a balanced combination of insulation, security, and practicality. Its detachable design allows for easy transportation and on-site assembly, making it suitable for various temporary and semi-permanent applications.

The frame is made of 2.5mm galvanized steel, with top/bottom beams and columns designed to withstand external pressures, ensuring long-term use in different environments.

Wall panels adopt 2510×950×50mm rock wool sandwich panels (double-sided iron sheet, 0.25mm thickness), offering excellent thermal insulation and fire resistance.

All components are pre-fabricated and detachable, reducing on-site construction time. The package includes complete hardware accessories such as m12×25 hexagon socket screws and structural adhesive for secure installation.

Equipped with 925×1200mm plastic steel sliding windows (2 sets) and a 925×1970mm steel single door, ensuring adequate ventilation and accessibility. The floor uses 1156×2820×18mm black glass magnesium boards for durability.

Construction site dormitories and offices

Temporary housing for disaster relief and emergency settlements

Outdoor events and exhibition booths

Remote area accommodations for mining, oil, and gas projects

Foundation Preparation: Ensure the installation site is flat and level. A concrete base or steel supports are recommended for stability.

Frame Assembly: Connect the top and bottom frames using the provided 2.5mm galvanized beams and columns, securing with hexagon socket screws.

Wall and Roof Installation: Attach rock wool sandwich panels to the frame, followed by roof tiles (980 type, 0.38mm thickness) and ceiling tiles.

Window and Door Fitting: Install plastic steel windows and the steel door, ensuring proper sealing with structural adhesive.

Floor Laying: Place black glass magnesium boards on the bottom frame, fixing them with wooden board nails (4.8×38mm).

Q: How long does it take to assemble the container house?

A: With 2-3 workers, assembly can be completed within 1-2 days under normal conditions.

Q: Is the house resistant to harsh weather?

A: The galvanized steel frame and waterproof roof tiles provide good resistance to rain and wind, suitable for most climatic zones.

Q: Can the dimensions be customized?

A: The standard size is fixed, but some components (e.g., door/window positions) can be adjusted upon request.

The 2.5mm thickness Detachable Packing Container House is a modular housing solution designed for flexibility and durability. Constructed with a 2.5mm galvanized steel frame, it features a standard external dimension of L5950×W3000×H2800mm, ensuring structural stability and resistance to corrosion. The house integrates high-quality components such as rock wool sandwich panels for walls, plastic steel sliding windows with anti-theft functions, and a steel single door, providing a balanced combination of insulation, security, and practicality. Its detachable design allows for easy transportation and on-site assembly, making it suitable for various temporary and semi-permanent applications.

The frame is made of 2.5mm galvanized steel, with top/bottom beams and columns designed to withstand external pressures, ensuring long-term use in different environments.

Wall panels adopt 2510×950×50mm rock wool sandwich panels (double-sided iron sheet, 0.25mm thickness), offering excellent thermal insulation and fire resistance.

All components are pre-fabricated and detachable, reducing on-site construction time. The package includes complete hardware accessories such as m12×25 hexagon socket screws and structural adhesive for secure installation.

Equipped with 925×1200mm plastic steel sliding windows (2 sets) and a 925×1970mm steel single door, ensuring adequate ventilation and accessibility. The floor uses 1156×2820×18mm black glass magnesium boards for durability.

Construction site dormitories and offices

Temporary housing for disaster relief and emergency settlements

Outdoor events and exhibition booths

Remote area accommodations for mining, oil, and gas projects

Foundation Preparation: Ensure the installation site is flat and level. A concrete base or steel supports are recommended for stability.

Frame Assembly: Connect the top and bottom frames using the provided 2.5mm galvanized beams and columns, securing with hexagon socket screws.

Wall and Roof Installation: Attach rock wool sandwich panels to the frame, followed by roof tiles (980 type, 0.38mm thickness) and ceiling tiles.

Window and Door Fitting: Install plastic steel windows and the steel door, ensuring proper sealing with structural adhesive.

Floor Laying: Place black glass magnesium boards on the bottom frame, fixing them with wooden board nails (4.8×38mm).

Q: How long does it take to assemble the container house?

A: With 2-3 workers, assembly can be completed within 1-2 days under normal conditions.

Q: Is the house resistant to harsh weather?

A: The galvanized steel frame and waterproof roof tiles provide good resistance to rain and wind, suitable for most climatic zones.

Q: Can the dimensions be customized?

A: The standard size is fixed, but some components (e.g., door/window positions) can be adjusted upon request.